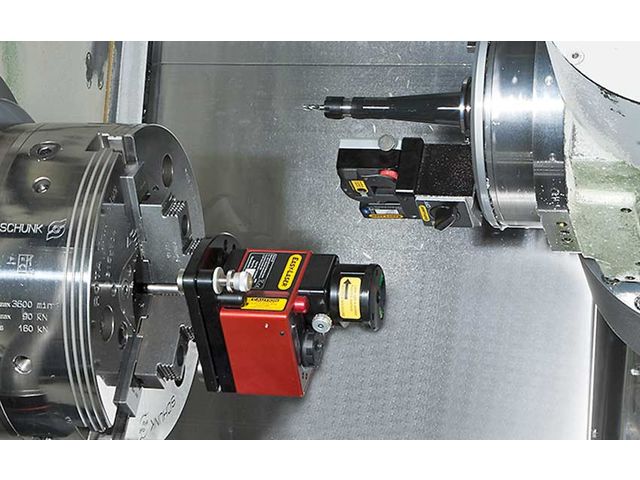

Easy-Laser E940 Machine Tool system is the market's most complete measurement system for measuring and aligning machine tools. You can measure straightness, flatness, squareness, spindle pointing directio, level and much more.

The transmitter's laser beam can be compared to an absolutely straight and weightless ruler, that is to say a perfect starting point for precision measurement. The measurement programs guide the user step-by-step through the measurement process with clear graphics and instructions on the large "5,7" colour display. It is also possible to use the measurement values directly and measure and adjust as required.

The system can handle most tasks in this field, despite the fact tha there is considerable variation in machine design: different types of lathe, milling machines, automatic drill, presses, water cutting machine etc. Some exampleof what you can check:

-

Straightness of machine axis

-

Sprindle direction

-

Sprindle to sprindle/ tail stock

-

Squareness between machine axis

-

Flatness on machine table or machineed

-

Bearing play check

-

Bearing condition

Compared tp conventionnal methods, such as dia gauges, mandrels and stones, work can be carried out much more quickly using a laser measurement system. And don't forget, the measurement result can be documented and compared to ISO10791-1 and 10791-2 used for machine tool. There are a lots of good reasons for investing in a laser system. One is that, becaus it is so quick to set up, the operator can check a machine much more often - if thee has been an accidental collision in the machine for example. Then compae with the machine documentation to see if everything is ok before continuing production. This can prevent costly production of parts that are out of tolerane. It can also extend the life of the tools.