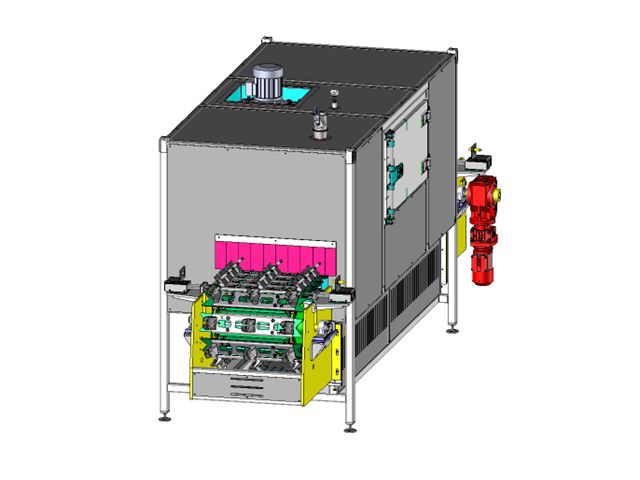

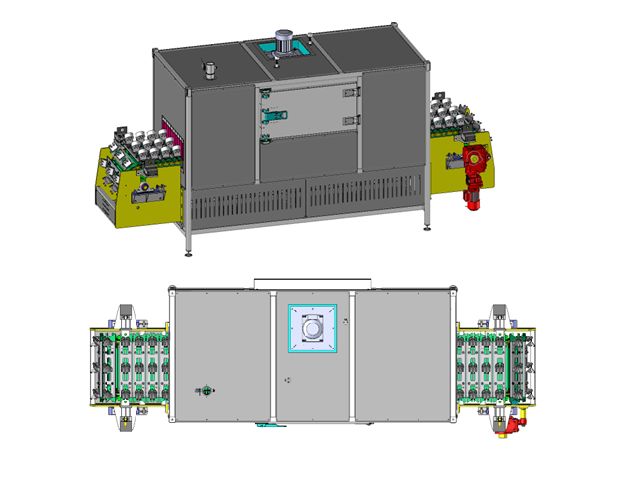

Continuous Oven or Tunnel Oven for Preheating with Scales Conveyor

Continuous Oven or Tunnel Oven for Preheating with Scales Conveyor - ELMETHERM SASU

Continuous Oven or Tunnel Oven for Preheating with Scales Conveyor - Tunnel oven

Continuous Oven or Tunnel Oven for Preheating with Scales Conveyor - produit présenté par ELMETHERM SASU

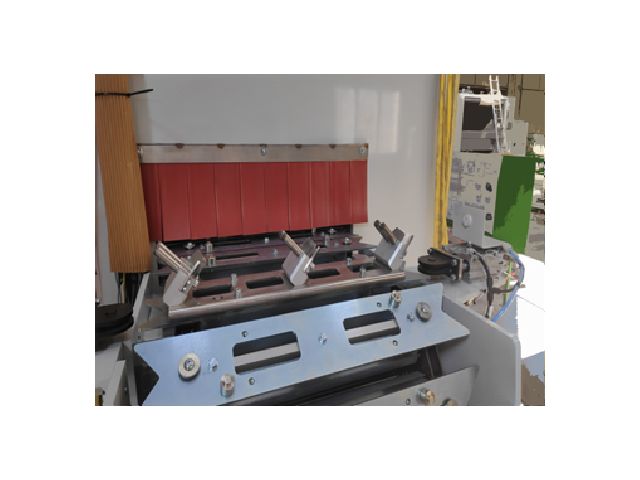

“ The preheating oven in combination with the scale conveyor allows the integration of automation, robots, into the heat treatment process. As the scales are floating, a scale position correction system allows the correction and repositioning of the scales to ensure that the robots can safely load and unload the parts without any incidents. ”

INTERNET USERS ALSO CONSULTED ON THE CATEGORY TUNNEL OVEN

See also

Buyers

Find your suppliers Complete your request and let our teams find you the best deals available.Suppliers

Find your future clients List your products and services to enhance your web presence and receive qualified enquiries.