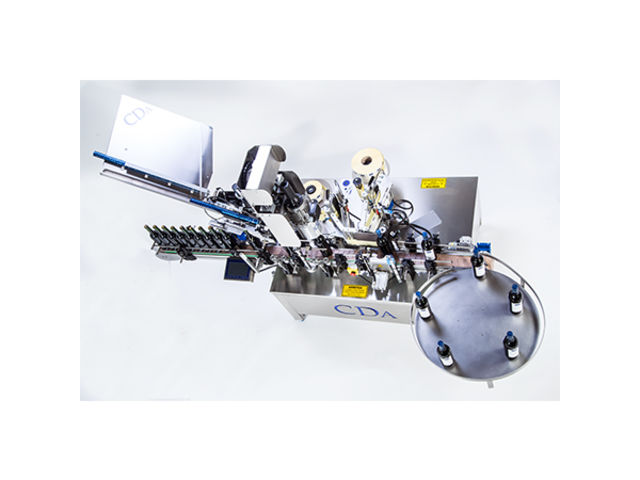

Labelling and Capsule Crimping Machine for Bottles - Régionale Model

Labelling and Capsule Crimping Machine for Bottles - Régionale Model - CDA Remplisseuses & Étiqueteuses

Labelling and Capsule Crimping Machine for Bottles - Régionale Model - Automatic labelling machines

Labelling and Capsule Crimping Machine for Bottles - Régionale Model - produit présenté par CDA Remplisseuses & Étiqueteuses

“ - Automatic labelling with a production rate of up to 1500 bottles/hour; - Thermal capsule crimping or 8-roller crimping; - Anodized aluminium conveyor; - Rotary receiving table for 60 bottles (Ø 700 mm); - Settings easy to manage via touchscreen; - Storage of label positions. ”

INTERNET USERS ALSO CONSULTED ON THE CATEGORY AUTOMATIC LABELLING MACHINES

See also

Buyers

Find your suppliers Complete your request and let our teams find you the best deals available.Suppliers

Find your future clients List your products and services to enhance your web presence and receive qualified enquiries.