juillet 10, 2018

ID-marking

juillet 10, 2018

ID-marking

juillet 10, 2018

ID-marking

janvier 02, 2018

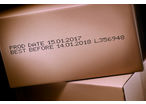

Package labelling

janvier 02, 2018

Package labelling

janvier 02, 2018

Inkjet marking

janvier 02, 2018

Thermal-transfer marking

janvier 02, 2018

Ink-jet marking

janvier 02, 2018

Ink-jet marking

décembre 01, 2017

ID-marking

novembre 16, 2015

Thermal-transfer markingMarkem-Imaje completes its range of SmartDate X series thermal transfer ribbons. In addition to its newly launched best-in-class SmartDate Xtra ribbons, Markem-Imaje introduces two other ribbon types: SmartDate Xpert and SmartDate Xceed. Designed to be used on its SmartDate coders, the entire ribbon range offers an array of quality identification solutions for all flexible packaging.

The high-end SmartDate Xpert ribbons are formulated for difficult environmental conditions. Their resin base allows for coding in extremely hot environments and offers a high level of resistance to oil, solvent and abrasion. They are capable of resisting temperatures as high as 250 °C and can be used on the SmartDate X60 up to speeds of 600 mm/s. “Customers can print ultra-sharp text, logos and high density graphics, including 2D codes. The new SmartDate Xpert ribbons are also the ideal solution for evolving needs, given their flexibility to code on all types of flexible material,” explains Stephen Kean, product manager for thermal transfer. They are also safe to use and are fit for the most stringent health and food regulations.

The SmartDate Xtra ribbons are the new market standard. Highly versatile, they allow customers to code all of their products with only one ribbon grade. Codes are 25% more durable than when using other comparable ribbons and ensure code remains legible throughout the production process and transportation. They come in 1100 m and 900 m lengths (versus 600 m market standard), limiting production downtime.

The basic level SmartDate Xceed ribbons are the most cost-effective ribbons to secure customer products without compromising on quality. Available in black and white, they are the latest generation of thermal transfer ribbons, manufactured to the latest standards, to ensure code readability and optimize SmartDate coder usage. Unlike wax ribbons, SmartDate Xceed ribbons are compatible with corner edge thermal printheads, resulting in enhanced quality codes at higher speeds and in more demanding environments.

The entire family of SmartDate X-Series ribbons is certified by Markem-Imaje. It allows customers to make the best of their SmartDate coders and benefit from all product warranties, including on the thermal printhead. Customers also benefit from a direct access to one single point of contact for worldwide expert support.

septembre 16, 2015

Inkjet markingManufacturer and global distributor for marking and printing solutions, Markem-Imaje is launching the 9450 E inkjet printer to meet productivity, contrast and adhesion needs for cable, tube and profile manufacturers.

Featuring a new-generation premium ink circuit and optimized printhead design, the Markem-Imaje 9450 E printer offers savings in time and money. It can print up to 3,000 km of cables, without printhead cleaning. Compared with other products of the same category and with equivalent resolution, the 9450 E prints 20% faster: up to 1,000 m/min for low diameter products such as optical fiber or wire harnessing applications.

Consumption of inks and additives is optimized. Additive consumption can be as low as 3 ml/h at 20°C and ink saving of up to 20%. Changing sealed cartridges is a clean operation, which does not require production shut-down. The printer automatically checks the reference and expiry date of the inserted cartridge, which reduces mistakes.

The 9450 E printer functions with a specifically formulated and tested range of inks offering strong contrast and perfect adhesion, even on dark substrates and those difficult to mark. These inks enable all types of material to be coded: PVC, LSZH, PP and even PE. Available in black, white, blue, yellow, orange, red and green, the inks are suitable for various uses: fast-drying and non-migrating inks, inks resisting direct sunlight, automotive fluids, water, friction and vulcanization.

The operator interface of the new 9450 E features dedicated sector functions. It proposes 5 different metric modes, from the most basic (repetition of metering) to the most complex (interleaving of different messages, choice of distance between messages). There is also an adjustment function to guarantee premium precision of the marking position, even at high speed (tolerance 2 mm).

Finally, it is possible to print text (up to 5 lines), barcodes, logos and symbols, in DIN or chimney mode, with character heights between 1 and 11 mm with a choice of alphabets.

septembre 16, 2015

Inkjet markingMarkem-Imaje launches its 9450 S, a new inkjet solution for the beverage industry designed to meet the sector’s demanding constraints for traceability, versatility and hygiene.

The new 9450 S printer guarantees that each product leaves the factory coded, that each code is right and that each code is and will be perfectly legible until it is consumed. Traceability is guaranteed with Mark & Read, an embedded system of coding and proofreading with a camera, directly on the user interface. Moreover, to be sure the right ink is used, the printer automatically checks the reference and best-before date of the consumable cartridges inserted by the operator thanks to its smart consumable system.

The 9450 S has been specifically designed to meet the sector’s demanding hygiene standards. It is made of stainless steel with IP56 (standard) and IP66 (option) protection rating. It can withstand high-pressure water cleaning and industrial detergents. Its design is smooth with no retention zones, which reduces bacterial contamination risks.

Totally versatile, the 9450 S printer is capable of coding 2 lines on the fastest existing production lines: up to 120,000 products per hour. With just one ink reference, the printer can code PET and glass bottles (including returnable glass), cans, liquid bricks, pouches, caps, wrapping films and shipping containers. This is a very useful solution when various containers are used in the same plant.

Several specialty inks are also available: a white ink that can resist the pasteurization process for dark glass, a permanent anti-counterfeiting ink to ensure brand protection, and a MEK-free ink for less environmental impact.

Operating costs of the 9450 S printer are up to 30% less than other competitive models. Ink consumption has been decreased thanks to specific fonts and optimized sector-specific resolutions. And like the entire 9400 range, the ink circuit design boasts a recycling system allowing a reduction of additive consumption of up to 2.5 ml per hour.

Like the 9450 printer, the 9450 S printer can carry out simple promotional coding operations by importing single codes from a USB thumb drive.

Lastly, from an integration standpoint, the 9450 S printer was designed to interface with equipment from major manufacturers such as Tetra Pak, Krones and Sidel. It is also compatible with the Weihenstephan standard.

février 20, 2015

Inkjet markingMarkem-Imaje, a worldwide manufacturer and distributor of product identification and traceability solutions, launches its new 9450. The 9450 is a continuous inkjet solution for all manufacturers regardless of their activity sector. Availability, performance, quality: the three pillars on which the new 9450 has been engineered to help optimize customers’ Overall Equipment Effectiveness (OEE).

The new 9450 printer has been designed to allow manufacturers to master their coding costs. With the new Longevity service pack, included in the initial purchase, customers benefit from a 5-year warranty on the pump, hence securing printer lifetime. Additive use and energy consumption have been reduced by an average 20% compared to other market brands and consumable changing is done on the fly without requiring line shutdown. Depending on the service agreement chosen, up to 99.9% availability ratio is guaranteed.

With a 7-inch color touch-screen, the 9450 printer offers optimum ease-of-use. Daily operations are facilitated by its intuitive interface, main printing performance indicator display and local language menus. Printer and printhead are full stainless steel with IP56 protection rating (IP66 optional) for pressurized water and detergent wash-downs and faultless operation in demanding environments, including extremely dusty ones.

To support brands in their objectives of international expansion, the new 9450 offers a large choice of printing possibilities; barcodes (including Datamatrix and QR), logos and alphabets, regardless of desired size and resolution. The 9450 can print up to 6.6 m/s and offers 2 resolutions: 71 and 115 dpi.

The 9450 also includes an option for editing unique codes that can be used for traceability or interactive gaming purposes organized by the brand. Easy to set up, this option brings promotional coding within reach of all manufacturers by simply inserting a USB flash drive.

A vast selection of inks – developed by Markem-Imaje - accompanies the launch. Black, color, permanent, thermo-chromic or high-contrast inks allow for optimum legibility on products. UV inks and inks with markers are also available to fight against counterfeiting and finally, environmentally-friendly inks complete the offer.

Last but not least, the new 9450 printer secures customers’ productions. The new real time Mark & Read vision system is accessible directly on the printer user interface. No need for an additional computer during installation. The Mark & Read system indicates faulty codes and allows for customers to take necessary action thus preventing product recalls which are costly in time, money and corporate image.

février 20, 2015

Inkjet markingMarkem-Imaje has announced the introduction of the 1200 integrated thermal inkjet printer, adding a new case coding solution to Markem-Imaje’s array of high-performance coders. Designed for rapid coding of secondary packages, the new 1200 produces high-resolution text, logos and high-density graphics on fast-moving production lines in the food, beverage, pharmaceutical and other industries. With a stainless steel casing and industrial-grade printheads, the new 1200 thermal inkjet printer is designed to excel in a variety of industrial settings, including those with dusty, humid or corrosive conditions.

Printhead options allow customers to print up to 203 mm (8 inches) high, with total control of variable horizontal DPI from 1 to 600, in 1-dot increments. This level of control helps customers improve print quality, minimize their ink usage and print with precision. The 1200 produces codes that are GS1 compliant at any speed, up to a maximum line speed of 201 meters per minute.

The printer is controllable from an easy-to-use, 7” touch screen with an intuitive WYSIWYG interface for simple set-up and continued operation. In addition, the 1200’s portable design means it can be set up quickly to accommodate production line changes.

The 1200’s case coding performance comes in part from its suitability for bulk ink delivery. Its bulk ink capacity is larger than any other case coding printer, at up to

2.7 liters. The 1200 also features a patented side jetting system with air regulation that works to decrease printhead starvation and flooding that can occur with bulk ink. The result is maximum performance with minimal downtime to boost total cost of ownership.

The 1200 thermal inkjet printer is fully compatible with Markem-Imaje’s powerful CoLOS coding software as an option for network control of all Markem-Imaje printers.

septembre 19, 2014

Laser marking

New laser technology provides customers and OEMS with the widest coding area on the market today for fast high-definition coding.

Markem-Imaje, a worldwide manufacturer and distributor of product identification and traceability solutions, has announced the introduction of the SmartLase C350 HD to extend Markem-Imaje’s array of product solutions. The SmartLase C350 HD offers the widest coding area currently available, up to 500x500 mm, as well as high quality coding capability.

A strong solution for laser coding on stick packs up to 1200 mm wide, dairy and yogurt pot lids up to 1000 mm wide, pouches and wide-web multi-lane applications, the SmartLase C350 HD is perfectly suited for food applications. It is capable of coding up to 1500 products per minute with optimum quality close to pre-printing and excellent contrast. Product integrity is also preserved: no chemicals, no piercing risks. The large marking area minimizes the number of printheads per line, for a smaller footprint and more efficient maintenance, contributing to an industry-leading TCO.

Further supporting food applications, the SmartLase C350 HD is designed for maximum flexibility. Text can be located anywhere on the packaging, and in any orientation. It makes last-minute customization possible, from product flavor to weight to promotional details, helping customers to reduce stock inventory.

This flexibility extends to coder configuration, as the C350 HD offers a choice of six lenses to adjust focal distance and coding areas, three detachable umbilical lengths, and two distinct user interfaces — remote intuitive touch screen or Web-based. The coder also features robust laser heads, with 30 watt IP55 or IP65 sealing protections, in two wavelengths. A specific L version for laminated films and ultra-thin foils is also available.

Finally, the SmartLase C350 HD is compliant in its standard offering with ISO13849 pld and Pack ML standards, and is compatible with a range of Markem-Imaje CoLOS networking software solutions for easy central management.

As part of the SmartLase C range of robust, reliable, high-performance coders, the new SmartLase C350 HD incorporates Markem-Imaje’s proven reliable SmartLase Code Technology, which gives 30% greater performance over an extended lifetime. Integration into the production line is easy due to its modular design. The IP65 option uses no plant air and no water, and in all configurations the coder features a dedicated fume extraction system for a cleaner, safer, odor-free working environment.

septembre 19, 2014

Laser marking

Markem-Imaje is enhancing its range of SmartLase C laser coders with a new version, SmartLase C350 BOU, whose design and technical features enable it to operate directly at the heart of bottle label applicators.

To bring the laser printhead closer to labels to be coded, Markem-Imaje has developed a flexible and adjustable extension, known as Beam Orientation Unit (BOU). This unit provides optimum distance for quality marking of up to 45,000 labels/hour. Several lengths of tubing are possible to adapt to all labeling configurations.

Enhancement of tightness and protection against dust is possible as a result of an (optional) IP65 protection rating for printhead and controller, certified by an independent laboratory. Laser connectivity with the labeler guarantees that no shot is made if a label is not present. In addition, a dust extraction system, ES500+, is proposed. An automatic flow control enables it to adapt to high-speed label coding.

The new SmartLase C350 BOU coder has the characteristics of the SmartLase C range already considered as a benchmark by leading plastic bottled water manufacturers and brewers: high production rate (up to 100,000 bottles/hour with the C350S version, for example) with flawless print quality. Codes are perfectly sharp and attractive fonts enhance the product. The laser source benefits from an extended life time of nearly 30% higher than other market models as a result of a cooling system which does not use compressed air.

Finally, low energy consumption ensures rapid ROI. Other benefits include heightened environmental performance and no more daily cleaning and maintenance operations.

septembre 19, 2014

Inkjet marking

The new Markem-Imaje 9028 inkjet printer has been conceived and engineered for industrialists with an eye for simplicity, evolution and autonomy. Ideal for small industrial application customers, the new 9028 offers excellent marking quality. As successor to the popular 9020 version, with over 40,000 sales, the new 9028 printer features several innovations for enhanced performance.

In particular, the new 9028 printer has been fitted with a completely rethought ink circuit (M6’) that can operate non-stop for over 2 years (on the basis of an annual operating time of 3,000 hours). Clean, practical and easily recyclable, the M6’ ink circuit can be replaced by operators themselves, in less than 6 minutes, by simply clicking it out and in with a single, supplied tool. An alarm system offers a high degree of flexibility where replacement programming is concerned. Last but not least – 15% less additive consumption.

At the consumable level, new inks are available: a range of high-adhesion inks for the most difficult substrates to be marked, a MEK-free quick-drying ink and a permanent ink. Consumables are presented in new sealed cartridges which display the quantity remaining with greater precision. Easy-to-handle cartridges are quick and clean to replace, without stopping production operations. Finally, 9028 cartridges are fully compatible and can be used on other Markem-Imaje models.

The 9028 printer has been designed to plug and print. A latest-generation system of printhead cleaning ensures instant daily startups and trouble-free restarts, even after several weeks of downtime. It is operational just a few minutes after installation. Finally, a stainless steel stand and an IP55 protection rating ensure that the 9028 printer can be installed in the toughest manufacturing environments, without any specific installation requirements.

Finally, as a worthy successor to the 9020 printer, the 9028 model codes most substrates (cardboard, plastic, metal...), prints up to 4 lines of data and can reach a speed of 4.4 m/s. Its user-friendly, intuitive interface can efficiently guide operators in their daily operations with total autonomy.

juillet 01, 2014

Laser markingMarkem-Imaje launches a new generation of SmartLase CO2 laser coders with performances 30% higher than market standards thanks to SCT (SmartLase Code Technology), an innovative patented technology.

The new SmartLase range meets the needs for higher speeds of the beverage industry. It is capable of coding up to 108,000 bottles per hour with a print quality and a code legibility unsurpassed to date. To improve traceability and fight diversion in the food industry, the print capacity of each code has increased from 30 to 120 characters.

The SmartLase range also offers an excellent availability ratio of the coding equipment. It can be up to 99.9% with a specific service contract. The laser source benefits from an extended life time of nearly 30% due to reduced laser duty cycles. Finally, the modular design of the SmartLase coders makes maintenance easy; the laser head can be changed in 10 minutes without alignments and a built-in sensor facilitates diagnostics by assessing the laser power.

Several versions are available; the new SmartLase range can print all types of products regardless of the production rate. Paper and cardboard are perfectly coded with the standard models C150 (10 W) and C350 (30 W). The C350 L (30 W) version is ideal for flexible packaging (BOPP) and laminated cardboards (PE). The C150 S (10 W) and C350 S (30 W) versions have been designed to code PET bottles, reducing the risk of piercing even if very thin. Other versions will complement the range in 2013-2014.

février 03, 2014

Thermal-transfer markingDesigned expressly for companies in the poultry, meat, fruit and vegetable and pre-made sandwich industries where frequent production line cleaning is a requirement, the new SmartDate X40-IP thermal transfer coder has been engineered to withstand water ingress.

Officially certified, this fully industrial solution is made of stainless steel. Its enclosures, specifically designed for humid environments, effectively keep out moisture during plant cleaning. All openings to the electronics are sealed including the ports for the connecting cable and USB.

With the SmartDate X40-IP, preparation for cleaning is very easy and user-friendly. The connecting cables do not have to be removed and a step-by-step process in the user interface guides the operator through the procedure.

The SmartDate X40-IP has also been designed so that customers can choose to protect either the printer or the controller or both, thereby reducing costs.

For companies already operating SmartDate X40 coders and using homemade solutions to protect their equipment during plant cleaning, IP upgrades by a trained Markem-Imaje service engineer are possible.

Finally, the new SmartDate X40-IP coder benefits from the already proven SmartDate technology. It can print large amounts of complex information on flexible packaging films. It delivers speed, quality and reliability thanks to an intelligent printhead that optimizes print quality and an efficient, waste-reducing ribbon. The extended ribbon length to 1,100 meters reduces ribbon changeovers and increase uptime.

Buyers

Find your suppliers Complete your request and let our teams find you the best deals available.Suppliers

Find your future clients List your products and services to enhance your web presence and receive qualified enquiries.