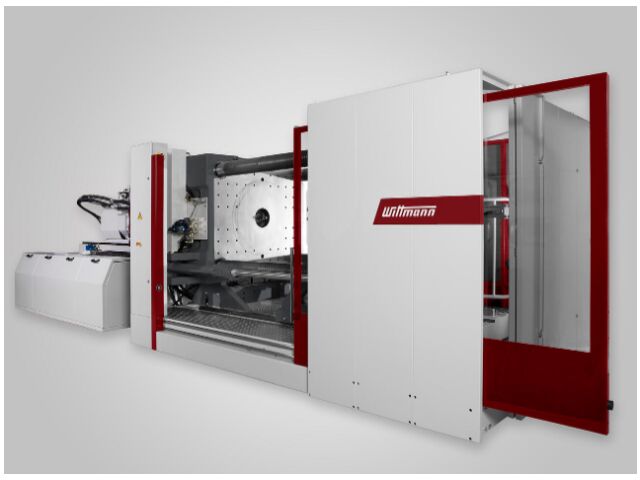

The MacroPower E Hybrid consists of a modern, servo hydraulic 2-platen clamping unit combined with an all-electric high-speed injection unit capable of 450 mm/sec injection speed. Its high dynamism, precision and energy efficiency enable the production of high-precision plastic parts with simultaneously minimal energy input. This makes the machine an ideal choice for molds with large numbers of cavities from the packaging and electronics industries, and for thin-walled, high-precision technical components.

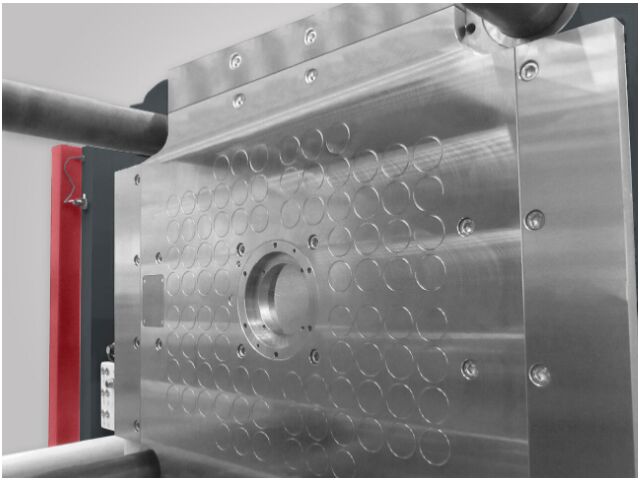

In the MacroPower E Hybrid, the clamping, ejector and nozzle movements run on a servo-hydraulic system. A highly dynamic servo motor is used as drive unit. The hydraulic pump is an electrically adjustable axial piston pump with a variable displacement volume laid out to meet the performance requirements of the clamping unit. Flow regulation is effected via the motor speed and/or the pivoting angle of the hydraulic pump.

The advantages

-

Combination of electric injection unit and servo-hydraulic clamping unit

-

Short cycle times through parallel operation of injection and clamping unit

-

High dynamism and precision through servo-electric injection unit

-

Small footprint thanks to compact design

-

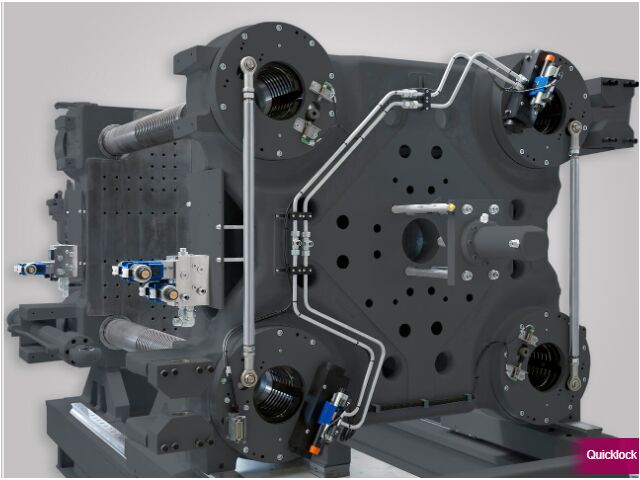

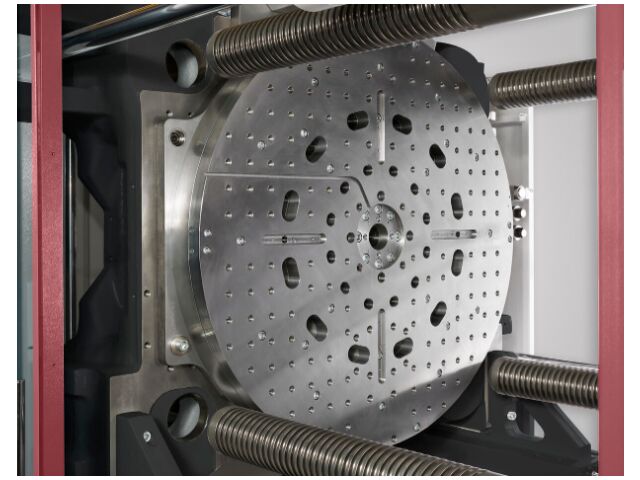

Generously dimensioned 4 tie-bar/2 platen clamping system

-

Long-stroke system to release the tie-bars facilitates mold insertion from the side

-

Fast locking through QUICKLOCK®

-

User-friendly new UNILOG B8 control system with integrated assistance systems

-

With WITTMANN 4.0 perfect integration of machine and peripherals in “plug & produce” system

-

Attractive price/performance ratio

The machine series

MacroPower E (Electric): 14 clamping force sizes from 400 to 1100 t

MacroPower standard: 19 clamping force sizes from 400 to 2000 t

MacroPower COMBIMOULD: for multi-component injection molding – from 400 to 2000 t